Image Source: Google

In the world of packaging, efficiency and speed are key factors that can make or break a business. One technology that has been revolutionizing the packaging industry is the best friction feeder machine. These innovative devices have transformed the way products are packaged, making the process faster, more accurate, and cost-effective.

What are Friction Feeder Machines?

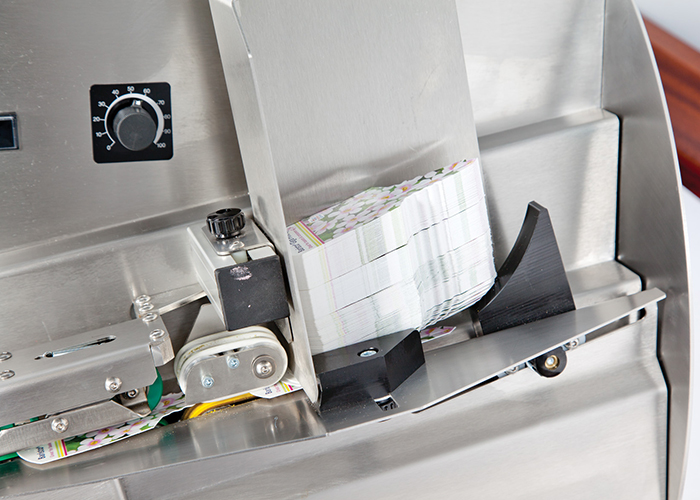

Friction feeder machines are automated devices used in packaging operations to feed various materials such as paper, cardboard, plastic, or metal into packaging systems. These machines utilize friction to accurately and efficiently feed individual sheets or items at high speeds, making them ideal for high-volume production environments.

How do Friction Feeder Machines Work?

Friction feeder machines operate by utilizing two sets of rollers – a friction roller and a feed roller. The material to be fed is placed between these rollers, and as they rotate at controlled speeds, the friction generated between the rollers and the material propels it forward. The precise control of the roller speeds ensures accurate feeding of materials into the packaging system.

Benefits of Using Friction Feeder Machines

- Increased Speed: Friction feeder machines can feed materials at high speeds, significantly enhancing the packaging process's overall speed and efficiency.

- Accurate Feeding: The precision control of friction feeder machines ensures accurate feeding of materials, reducing errors and improving product quality.

- Versatility: These machines can handle a wide range of materials, making them suitable for various packaging applications.

- Cost-Effective: By automating the feeding process and reducing errors, friction feeder machines help lower production costs in the long run.

- Easy to Operate: Friction feeder machines are user-friendly and easy to set up, requiring minimal training for operators.

Applications of Friction Feeder Machines

Friction feeder machines find applications in various industries where efficient and accurate feeding of materials is essential. Some common industries that benefit from these machines include:

Printing and Packaging

In the printing and packaging industry, friction feeder machines are used to feed paper, cardboard, and other materials into printing presses or packaging lines. This ensures a smooth and uninterrupted production process, increasing productivity and reducing downtime.

Food and Beverage

Friction feeder machines are employed in the food and beverage industry to feed packaging materials such as wrappers, labels, or cartons into packaging machines. This helps maintain hygiene standards and ensures the efficient packaging of food products.

E-commerce and Fulfillment

E-commerce companies and fulfillment centers utilize friction feeder machines to automate the packaging process for shipping orders. These machines can handle various packaging materials, streamlining the order fulfillment process and improving customer satisfaction.

Choosing the Right Friction Feeder Machine

When selecting a friction feeder machine for your packaging operation, consider the following factors:

Speed and Capacity

- Determine the speed and capacity requirements of your production line to ensure the friction feeder machine can meet your demands.

Material Compatibility

- Ensure the machine is compatible with the materials you will be feeding to avoid issues such as jams or misfeeds.

Ease of Maintenance

- Choose a machine that is easy to maintain and clean to minimize downtime and ensure optimal performance.

Cost and ROI

- Consider the initial cost of the machine, as well as the potential return on investment in terms of increased efficiency and reduced production costs.

Conclusion

Friction feeder machines have become indispensable tools in the packaging industry, offering unparalleled speed, accuracy, and efficiency in material feeding operations. By understanding their working principles, benefits, applications, and factors to consider when choosing one, businesses can revolutionize their packaging processes and stay ahead of the competition.